Kaolin vs Kaolinite: Understanding the Key Differences

Kaolin and kaolinite are often confused with each other. They are inextricably linked — the commercial and mineralogical sides of the same coin — but understanding the difference is important. Kaolinite is a mineral species; kaolin is a rock or rock group of which kaolinite is the most common constituent.

This guide outlines the properties, structures and role in industry of polymers so you can select the best polymer for your application.

What Is Kaolinite?

Kaolinite is a phyllosilicate mineral, a type of aluminosilicate mineral, and has the formula Al_(2}Si_{2}O_{5}(OH)_{4}. It is one of the phyllosilicate class of industrial minerals.

Mineralogically, it is a 1:1 layer silicate, consisting of one tetrahedral layer of silica sheets bonded through oxygen to one octahedral layer of alumina.

The distinct structure utilizes this crystallinity resulting in the minerals unique physical properties, including a lustrous luster, low cation-exchange capacity, and a soft earthy feel.

Usually it is white and powdery, although a colored powder may occur due to pollution. Kaolinite also is part of a larger clay category, kaolin, so we will start our discussion of this clay type with the most basic unit, kaolinite itself.

What Is Kaolin?

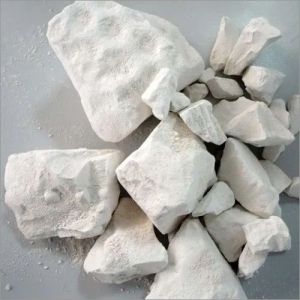

Kaolin, known as “China Clay” is a basic soft white clay that is used for many industrial processes. Kaolin is a term for a naturally occurring clay rock which is rich in kaolinite — the mineral — and is not a pure mineral like kaolinite.

It may also contain different amounts of other minerals such as muscovite, quartz, feldspar, and anatase in its diseased state. Commercially, kaolin is appreciated for its whiteness, small particle dimensions, and chemical inertness. It is mined across the globe and processed into various grades (such as hydrous or calcined) to suit the needs of the different manufacturing industries.

Key Differences Between Kaolin and Kaolinite

The main difference is that kaolinite is a mineral and kaolin is a rock/clay. Kaolinite is thus a certain “addition” and kaolin is an “assemblage” with a distinct abundance of this addition.

On the other hand, kaolin is an amorphous material and its chemical composition can also vary significantly depending on the geographical area and the deposits (which can contain diverse types of impurities), so it doesn’t have a fixed formula as kaolinite. The term “kaolinite” may be used in industrial mineralogical contexts but “kaolin” may be the preferred term in purchasing, shipping, and large-scale production situations. One is a scientific concept; the other, a marketable commodity.

Industrial Applications

These versatile properties are one of the reasons why both materials play a key role in a number of industries:

- Papermaking:–Kaolin can serve as a paper filler and paper coating to improve the brightness, smoothness and the printing performance of the paper.

- Ceramics – Due to its high melting point and white-firing characteristics, it is used in porcelain and sanitaryware.

- Paints and Coatings: Here, it acts as an extender for the pigment, enhancing opacity and performance in various coatings.

- Rubber &Plastics :Its an reinforcing filler with improvement of mechanical strength and dimensional stability.

- Pharmaceutical and Cosmetic – Since it is highly inert, it is used in facial masks and excipient in tablet formulation.

Why the Difference Matters

This differentiation is key in terms of quality assurance and technical specifications. If a “pure kaolinite” is needed, chemical behavior along with 1:1 structure is needed by the researcher.

However, when a manufacturer buys “kaolin”, they are not buying it by name but a bulk semi-processed raw material with specific properties such as brightness, grit content etc.

Correct usage of these terms assists in communication between geologists, engineer, and procurement personnel. Moreover, the knowledge that kaolin must contain impurities will allow the mfrs to adjust their formulations to correct for undesirable hue or strength over interfering minerals in the finished articles.

Shree Ram Kaolin: A Trusted Source for High-Purity Industrial Minerals

Shree Ram Kaolin, your ultimate destination to acquire the best industrial minerals. Focusing on high-purity kaolin for a variety of industrial applications, they produce quality products having precise brightness and consistency.

As you can see, from paper coating materials, premium quality ceramics to specialty rubbers, Shree Ram Kaolin provides reliable solutions to facilitate and augment the manufacturing process.

They have achieved this mix of excellent standing in the mineral industry due to their technological knowledge and dedication to customer satisfaction. Check the complete product range & tech specifications at shreeramkaolin.com.

Conclusion

Although kaolin and kaolinite are related terms, it is necessary to make the distinction between the mineral and the commercial clay where kaolin implies kaolinitic clay. The white color and plasticity of kaolin are a result of the presence of a crystalline phase known as kaolinite.

Recognizing these distinctions helps industries understand their production and select the most suitable grade of clay for their various applications. These materials, as we have witnessed, are the backbone for everything from the paper that we peruse for information to the porcelain that we often use to house food. Identification and sourcing provide the foundation for excellence in manufacturing and product development.