Silica sand, primarily composed of silicon dioxide (SiO₂), is crucial in the glass industry due to its high purity and unique properties. With a purity typically above 99%, silica sand ensures the clarity and strength of glass products.

Its high melting point (1,710°C) allows it to withstand the intense heat required for glass formation, while its chemical stability prevents unwanted reactions during the process.

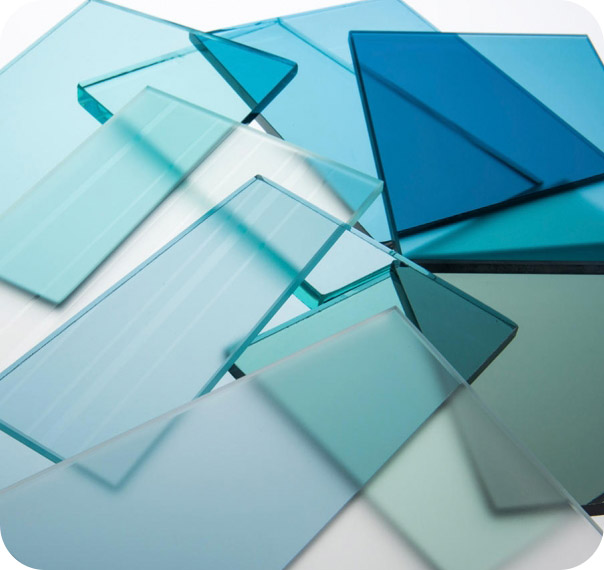

Different types of glass, such as container glass, flat glass, and specialty glass, demand varying grades of silica sand. For instance, container glass for bottles and jars, and flat glass for windows and mirrors, both require high-purity sand for optimal quality. Specialty glass, used in laboratory equipment and optical applications, needs ultra-high-purity silica sand to meet stringent performance standards.

The glass production process involves batching, where precise amounts of silica sand and other materials are mixed, followed by melting in a furnace at around 1,700°C. The molten glass is then formed, annealed to remove internal stresses, and inspected for defects. Sustainable mining practices are essential to mitigate the environmental impact of silica sand extraction. Economically, the availability of high-quality silica sand is vital for the glass industry’s success, underscoring its indispensable role.

Why Is Silica Sand Quality Important For Glass?

High-quality silica sand ensures clear, strong, and defect-free glass by providing consistent purity and performance.

What Types Of Glass Use Silica Sand?

Silica sand is used in container glass, flat glass, specialty glass, and glass wool.

How Should Silica Sand Be Sourced For Optimal Glass Quality?

Look for silica sand with high purity, consistent grain size, and reliable suppliers to ensure the best glass quality.